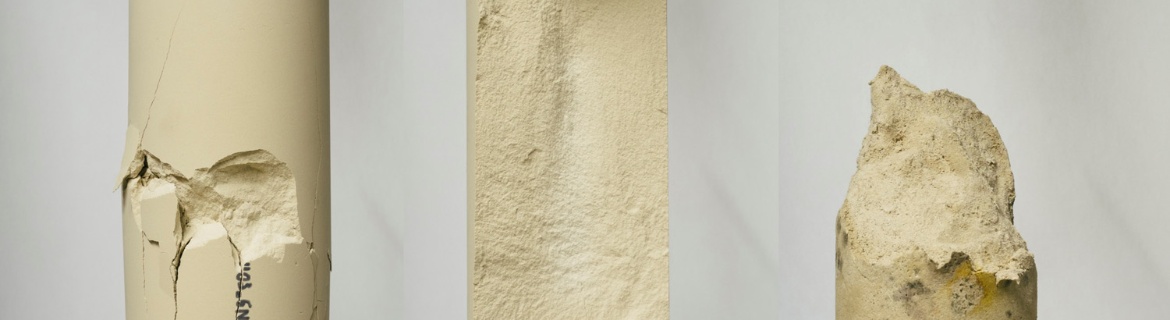

The test lab is equipped with three test machines for experimental determination of mechanical parameters for use in teaching and research.

It is a valuable resource for testing innovative components, supporting structures and materials for architectural and building applications which are frequently developed in the context of student projects in conjunction with current research activities or collaboration with partners from industry. The three testing machines, with different test forces, fixtures and accessories for tension, pressure and bending tests make it possible to test the load-bearing capacity of a broad spectrum of prototypes.

The test lab is equipped with a servo-hydraulic system (Schenk S59) with a test force of 400kN for static, dynamic and cyclical tests. The test room measures approximately 4.2x2.3x1.0 m.

Two other systems (Zwick) with test forces of 100kN and 20kN respectively, allow accurate testing of smaller test items. The first is fitted with an integrated extensometer and a heat chamber (b/h/d = 400/500/600 mm) for temperatures of up to 250°C.

The data measured is recorded using universal data loggers (QuantumX, Spider8) allowing, for example, measurements with inductive path recorders and strain gauges. The test lab permits a wide range of mechanical tests, for example on glassfiber reinforced bridge deck elements, laminated glass, wooden connecting elements or composite components made of CFCs and concrete.

Test lab

Breitscheidstr. 2, 70174 Stuttgart, 1st UG (basement) - Room 01 - Michael Tondera

- 0711 / 685-83207 oder -82776

- Write e-mail

- Tue – Fr: 1pm – 5.00pm Uhr Fr: 09.00am – 12.00am